Sustainability: The Future of Business

In the business world, sustainability is an incredibly important issue for many people. The primary reason why we need to care for our planet is pretty obvious: So that everyone can continue to thrive on it.

Business sustainability is the practice of efficiently operating a business without impacting the environment negatively. Sustainability helps businesses to be more efficient, innovative, achieve better growth and reinforce stakeholder relations. An environmentally aware business considers more than just profits, it considers its impact on society and the environment.

The United Nations has outlined 10 major principles to achieve environmental sustainability with responsible manufacturing

Sustainability: Starts With Responsibility

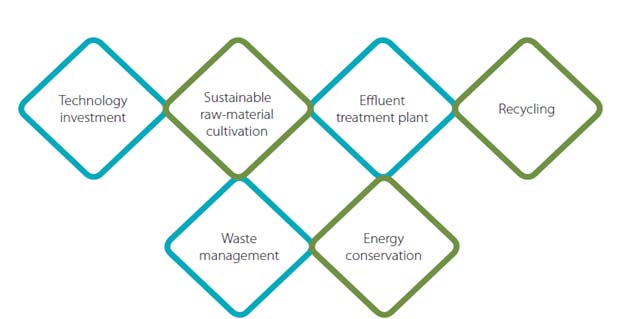

BCML’s sustainable development is directed to address the needs of today while protecting, sustaining and enhancing the natural resources that will be required in the future. The company adheres to the principles set by the United Nations while performing its day-to-day operations in an environment-friendly manner. To create a sustainable future, it makes sure not to leave any toxic impact on the environment with what the company practices and promotes. To strengthen long-term sustainability, the company has also made proactive and significant investments in multiple areas to moderate carbon footprint and costs. It has also undertaken various initiatives to enhance environment integrity.

Waste Management

Waste management includes all of the processes and activities that include handling waste materials efficiently. The primary objective of waste management is to minimize pollution and utilize waste as a resource. It is the best way how a company can perform their roles in the greenest way possible. When it comes to Indian sugar manufacturing units, the wastes generated are pressmud, bagasse, molasses etc. This wastes can be put to a number of uses with the help of waste management.

The company reuses waste products and byproducts to reduce disposal, emissions and discharge. It makes use of waste/by-products like bagasse and molasses to manufacture downstream products. The filter cake generated during the operations is also distributed among the farmers as organic manure. The company also rented brick kilns to store the fly ash generated out of boilers.

Water Management

Needless to mention, water is an extremely sacred resource and is at the core of sustainable development and the survival of everything living and breathing on the planet. Water management teaches us to utilize a limited amount of water whenever required. This keeps every citizen accountable for any wastage of water that occurs.

The Company complies with the Central Pollution Control Board’s effluent treatment norms. It installed diverse new technologies like RO and advance oxidation based Condensate Polishing Units (CPU). Ion Exchange column rinse water recovery system (UF and double stage RO base) and excess hot condensate separate cooling tower recycle the excess water during the sugar manufacturing process to minimize the use of ground water. In light of waste water treatment, for the first time in the sugar industry, the Company installed a sulphate removal system at its various double sulphitation units.

Emissions

Bagasse is widely used as a fuel in all cane-based sugar mill boilers in India. When bagasse burns in boilers, it produces particulate matter, oxides of nitrogen, carbon, sulphur and water vapour. The emissions of Bagasse-fired boilers are within the limits prescribed by the pollution control authorities. As per general emission standards, 150 Mg/Mn3 is the benchmark for particulate matter released into the atmosphere by bagasse fired boilers. The particulate matter is known as fly ash which consists of ash, unburnt bagasse and carbon particles. If air pollution control equipment is not installed at the sugar processing units, fly ash can get released into the atmosphere through the chimney. The Company has made some heavy investments in emission control by way of ESP, bag filters and scrubbers. It has also implemented online systems to monitor emissions across its manufacturing units.

Effluents

Effluents in sugar factories are generated from mill house, boiling house and spray pond. The Company was among the first in Uttar Pradesh to install incinerators in distilleries and has also invested in new boilers. The Company also installed a granulation plant in its distillery units to produce granules which is distributed as fertiliser to the farmers at subsidised rates. Last but not the least, the Company sealed all outgoing drains from its manufacturing units ensuring zero liquid discharge.